PPT Repetitive Manufacturing PowerPoint Presentation ID781901

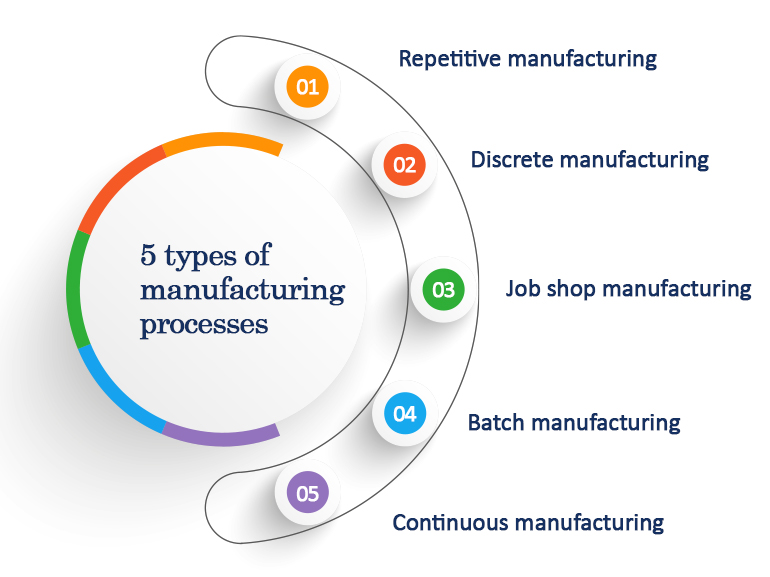

Empat strategi yang dapat dipilih antara lain: (1) process focus, (2) repetitive focus, (3) product focus, dan (4) mass customization.. Salah satu syarat repetitive focusdapat dilakukan adalah terdapat modules (komponen yang dipersiapkan sebelum dirakit menjadi satu produk).

What is Repetitive Manufacturing? (with pictures)

Repetitive manufacturing is executed with schedules rather than work orders. Schedules require fewer steps and less paperwork to execute and are typical in manufacturing environments that use assembly lines to produce similar products using the same process. Since the same activities are repeated regularly, there is little variation.

SAP PP Repetitive Manufacturing Process YouTube

September 19, 2023. A repeatable process is a procedure that can be done the same way for a single outcome. Let's learn how to build and document repeatable processes to strengthen your team. A repeatable process is any activity that you can do again and again, expecting the same outcome. However, in order to get that same outcome, you need to.

PPT Chapter 5 PowerPoint Presentation, free download ID5570796

The process focuses on low volume, high variety products are also called job shop. These facilities are process focus in terms of equipment, layout, and supervision. Repetitive focus; falls between the product and process focus. The repetitive process is a product-oriented production process that uses modules.

Repetitive Manufacturing and What Crafters Can Learn from It

Robotic process automation (RPA) is a software technology that makes it easy to build, deploy, and manage software robots that emulate humans actions interacting with digital systems and software. Just like people, software robots can do things like understand what's on a screen, complete the right keystrokes, navigate systems, identify and.

Components of repetitive manufacturing ERP123 A Better Approach to ERP

Repetitive and Product-Oriented Layout Product-oriented layouts are organized around products or families of similar high-volume, low-variety products. Repetitive production and continuous production, which are discussed in Chapter 7, use. - Selection from Operations Management: Sustainability and Supply Chain Management, Twelfth Edition [Book]

The Repetitive Process of an ATheoretical Affective Intervention. Download Scientific Diagram

5 langkah dari proses iteratif. Proses iteratif dapat membantu Anda selama siklus proyek. Selama langkah-langkah proses iteratif, gol dan persyaratan Anda akan berfungsi sebagai titik awal proyek. Kemudian, tim Anda akan menggunakan pengujian, pembuatan prototipe, dan pengulangan untuk mencapai hasil terbaik. Berikut caranya: 1.

Advantages and disadvantages of repetitive manufacturing Made in Britain

The dynamics of a differential linear repetitive process are described by the following state space model defined over 0 ~ t ~ a, k ~ 0 Here on pass k, Xk(t) is the n x 1 state vector, Ydt) is the m x 1 vector pass profile and ud t) is the 1 x 1 vector of control inputs. To complete the process

Repetitive Manufacturing Examples In Powerpoint And Google Slides Cpb

1. Describe the basic characteristics of repetitive projects. 2. Make an analogy between repetitive projects and serial production lines. 3. Formulate a cost function considering direct and indirect cost items. 4. Employ mathematical models for scheduling the repetitive projects.

Process Strategies Process focus, Repetitive focus, Product focus, Mass customization POM

Repetitive manufacturing is a manufacturing process which produces products for rapid production flow. A distinguishing characteristic of repetitive manufacturing is its use of assembly/production lines. Manufacturers use this method when they are making products which are similar in design. Any variations in the product's design will be.

The 3Step Process for Automating Repetitive Tasks Asian Efficiency

Repetitive manufacturing is a form of mass production that relies on making high numbers of identical units in a continuous flow. This type of manufacturing is suited for a number of applications and is used in factories all over the world. Many companies specialize in developing equipment and techniques designed for such production processes.

Advantages and Disadvantages of Repetitive MFG Excell Metal Spinning

Repetitive manufacturing procedure: A schedule consists of production orders with completion date that falls in the same period. The production orders under a schedule (with like delivery schedule) can be grouped by item where different routing and production facilities are used for the same item. Alternatively, production orders may be grouped.

Repetitive Manufacturing Process Diagram (Oracle Work in Process)

A repetitive process makes a series of sweeps, or passes, through a set of dynamics over this finite duration and when each is complete the process resets. Moreover, the output produced on the previous pass explicitly contributes to the dynamics produced on the next one. Hence they can also be viewed as a class of periodic systems.

Repetitive Manufacturing Definition, Types, and Benefits Inbound Logistics

Repetitive manufacturing is a production method involving the mass production of identical products, typically on a regular or continuous basis. Repetitive manufacturing is typically used for high-demand products and products with a stable production process. The repetitive manufacturing production process is highly standardized and optimized.

What is Repetitive Manufacturing? (with pictures)

Repetitive Manufacturing gives you the ability to schedule outside processing by external suppliers into your repetitive manufacturing process. Related Articles: 16 Frequently Asked Questions About ERP. Implementing an enterprise resource planning software, also known as ERP, oftencatches businesses off guard. Most businesses underestimate the.

5 types of manufacturing processes & their advantages

The implementation of repetitive processes and the commitment to continuous improvement ensured that genset production quickly hit a regular drumbeat across a period of around 13 weeks. The project was completed on time and to budget, and Kohler is now working with the engineering contractor on other global data center projects.