Heat & Mass Transfer Mechanical Engineering Purdue University

Heat Sink Design Guide & Considerations. Thermal Heat Sink Compound Conditions - The goal is to not only have a well-rated thermal heat sink compound, but also want to ensure it is only as thick as it needs to be to fill the gap between the component and heat sink. If the gap is too thick, it may slow heat transfer. Natural and Forced.

heat sink design Advanced Thermal Solutions

Solar gain (how much heat is generated as sun is absorbed in the building) is controlled by the building's design and orientation, opaque-to-glazed areas ratio, heat reflection percentage,.

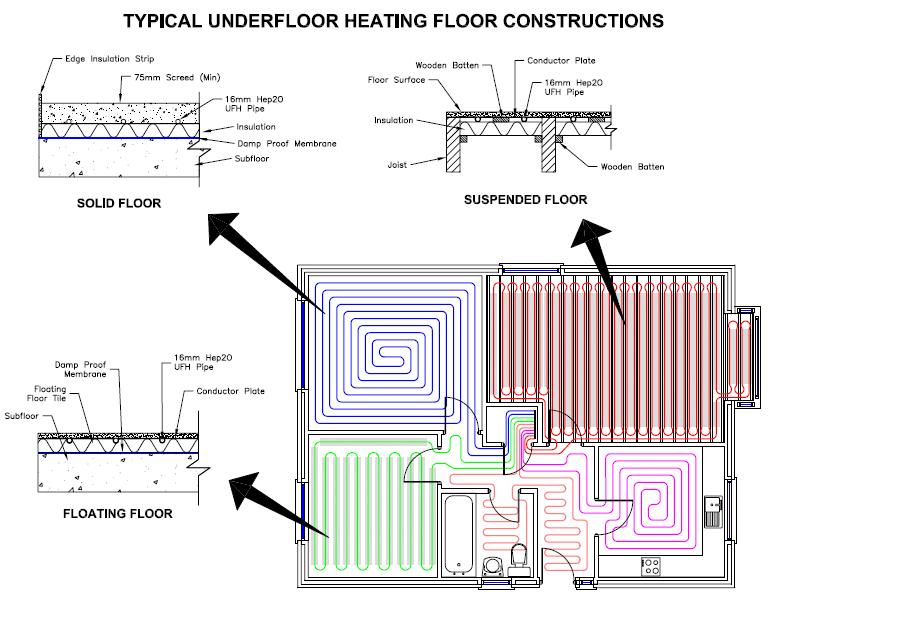

Radiant Heating Systems Watts

A Beginner's Guide to HVAC Design To plan a heating and cooling system, and choose the right equipment, get to know Manual J, Manual S, and Manual D By Scott Gibson | May 8, 2020

Heat Design Vitae 6KW Image 2 Chimney and Stove Services Ireland

HVAC Design - Basics This pathway is the first step in an HVAC&R design professional's learning beyond the structured academic environment. The sources are introductory in nature to assist those new to the industry as well as provide direction to others who simply want to improve their fundamental design knowledge and skills.

In Floor Radiant Heating Mechanical Extremes

The principles of HVAC design include the basic theory of system operation and the factors that determine the size and capacity of the equipment installed in the system. Once you have an understanding of the basics, you'll be given information concerning the different types of air conditioning systems.

Heat Design (debbbiethomas) Twitter

Section 6.2.7 of ASHRAE 62.1-2016 allows the ventilation-zone airflow (Voz) and/or the outdoor-intake airflow (Vot) to be reset as operating conditions change for HVAC systems. The design Vot is calculated for the worst-case scenario. The building is fully occupied and all terminal units are at minimum heating airflow.

Heat Design Firewarm 12kW (Rectangle with Arched Top) Replacement

Heat sink design basics are all about selecting the right geometry for a heat sink to affix to high power components, which then needs to be paired with other cooling strategies. There are many off-the-shelf options for heat sinks, all with slightly different form factors, masses, and materials. Manufacturers will also supply or recommend heat.

Natural Design for Heat Sinks — LED professional LED Lighting

According to the DOE, energy recovery equipment can provide energy savings of 15% or more. Figure 3: The control sequence of operations on a smart HVAC system does not incur any additional costs and could save building owners and developers 15% on their overall energy bill. Courtesy: Jordan & Skala Engineers.

Heat exchanger design handbook

Generally, heat sink design is a multi-objective problem in pursuit of high heat transfer, low resistance, light weight, high compactness and high strength. At present, the improvement of the thermal performance of heat sinks encounters many bottlenecks and demands the implementation of new designs, new materials, and flexible manufacturing..

HEAT DESIGN E600 ELECTRIC HEATER INSTRUCTION MANUAL ManualsLib

Its performance is also determined by the shape and design of its fins. Optimizing the shape and size of the fins helps to maximize the heat transfer density. Through modeling, the performance of different fin shapes and configurations can be evaluated. 4. Heat Sink Fins: Electronics Cooling Efficiency.

Radiant Heat Radiant Heat Layout Design

The system can exchange heat and energy between the two airflows, pre-cooling and dehumidifying in warmer seasons, and humidifying and pre-heating in cooler seasons. Depending on the system and building design, energy recovery systems can often provide up 30% more ventilation air than required by code without higher energy costs.

Heat Design Vitae 6kw The Fireplace Factory

Combined heat and power (CHP), or cogeneration, is the simultaneous generation of useful mechanical and thermal energy in a single, integrated system. CHP can be configured as a topping or bottoming cycle. In a typical topping cycle system, fuel is combusted in a prime mover, such as reciprocating engines, combustion or gas turbines, steam.

Heat Design (heatdesignnews) Twitter

Heat Sink Design Basics: Factors & Calculation June 24, 2022 Heat sinks are the easiest component to overlook in machinery and electrical circuits. But this is not the case when designing hardware because heat sinks serve a very crucial function.

Redken Heat Design 09 150ml

Heat Sink Design Thermal Resistance Calculator. Designing a heat sink also comes with understanding some calculations related to thermal resistance. The equation below is used to calculate the Thermal Heat Resistance (R hs) Rhs = (Tj-Tmb/P) - (Rth-jc) - Rinterface. Tj: Maximum junction temperature of the device in 0C.

Keeping It Cool with Innovative Heat Sink Designs Architectural

Heating, ventilating, and air-conditioning (HVAC systems) account for 39% of the energy used in commercial buildings in the United States.. HVAC systems are sized to meet design heating and cooling conditions that historically occur only 1% to 2.5% of the time. Thus, HVAC systems are intentionally oversized at least 97.5% to 99% of the time.

Diffusion In Solids And Liquids Heat Transfer Microstructre Properties

Heat Design Equipment Inc. manufactures infrared heaters for asphalt construction and repair, using patented, state of the art technology. PAVING PRODUCTS Learn More ASPHALT PATCHERS & HEATERS Learn More ASPHALT RECYCLING Learn More MINI HEATERS Learn More THERMOPLASTIC HEATERS Learn More COMBINATION UNITS Learn More ASPHALT STORAGE Learn More