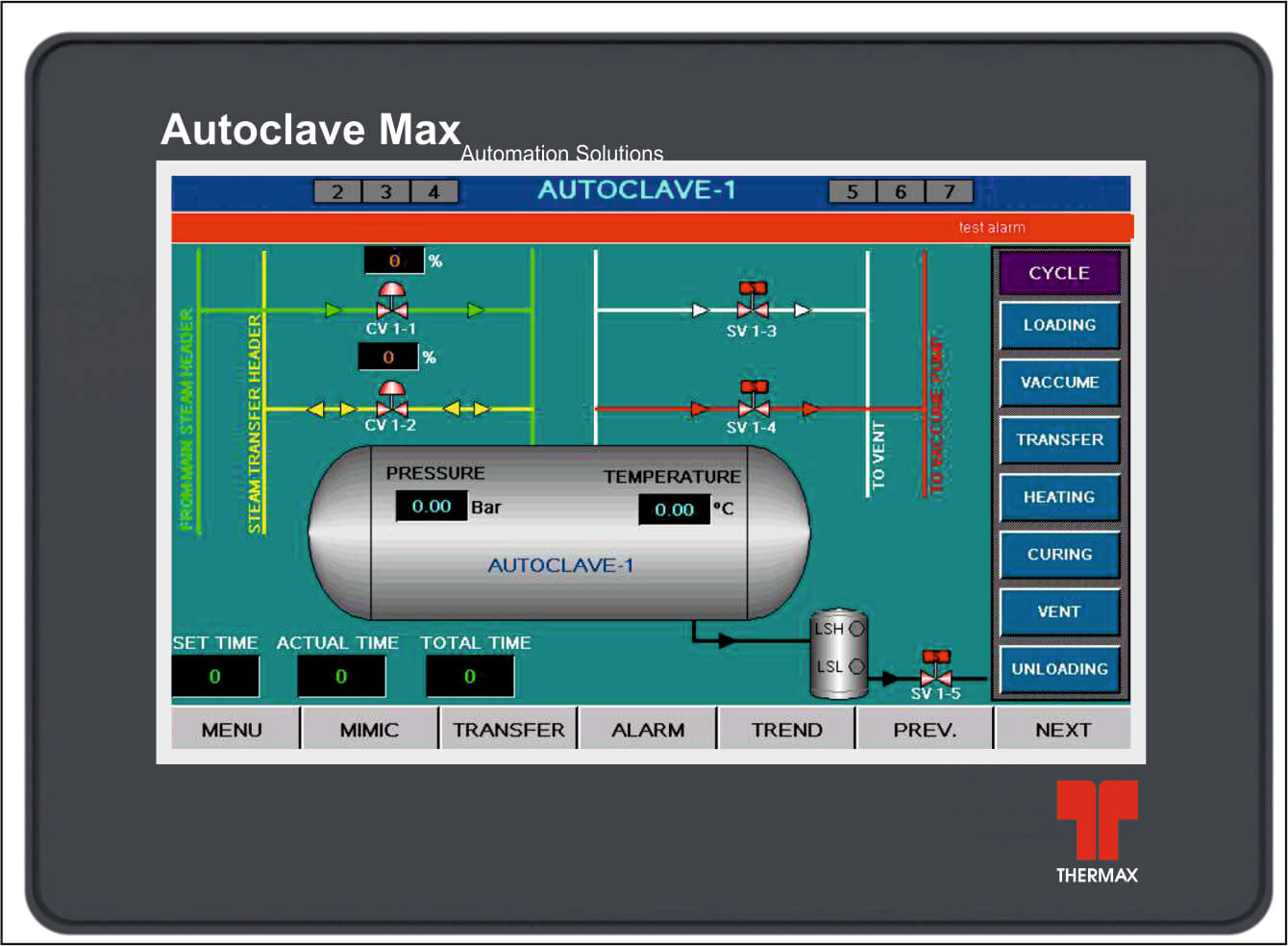

Autoclave Automation Thermax

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis.

Autoclave Control System XIRTUE Autoclave, Composite Autoclave

Our autoclaves come equipped with the Tactrol® 2 Control System, which provides both safety and efficiency features as well as enabling you to automate the sterilization process. This includes automatic timed freesteaming, which improves air removal and sterilizing performance.

Autoclave Sterilization Steam Control System Upgrade YouTube

Bondtech is pleased to offer a host of autoclave designs for everything from medical equipment sterilization to ceramic core leaching. Below is a summary of our most popular autoclaves.. Our state-of-the-art EnVision process control system allows users to ensure that saturants completely reach the interior of the wood product, thereby.

Custom Autoclave Integration Solutions Beta Star Life Science Equipment

The autoclave is a sealed device (similar to a pressure cooker) that kills microorganisms using saturated steam under pressure. Table of Contents Principle Components (Parts) of Autoclave Types of Autoclaves Based on size Types of Autoclave on the basis of Working Principle Procedure Sterilization control Biological indicator Autoclave tapes

WSF SmartClave® Autoclave Control Systems by WSF Industries, Inc.

Anchor Autoclave Systems (Houston, Texas, U.S.A.) provides the Sentinel controller with most of its custom autoclaves. Anchor evaluated a number of other control systems, but the Sentinel proved to be the most cost-effective, providing a more versatile control system for about the same price as conventional controllers.

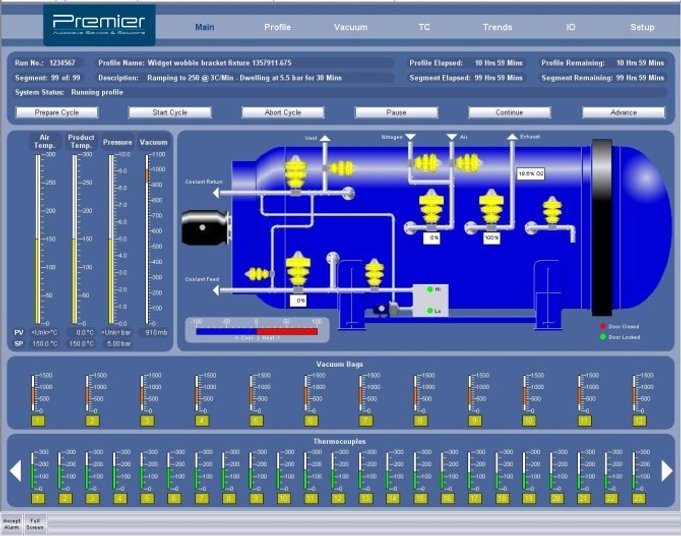

Composite curing autoclave control system demonstrations available

ASC Process Systems is the world's leading manufacturer of autoclaves and ovens for the aerospace, composites, nuclear, vulcanizing, and glass industries. We have been in business for over 30 years and are the recognized leader in autoclave and control system technology. The majority of aerospace companies standardize on ASC's products.

Ve Programming Control Starter Kit Autoclave Control System

The Econoclave® is the only autoclave that comes with ASC's Composite Processing Control (CPC) system. CPC is a PC-based control solution designed specifically for composite curing autoclaves and ovens. It is by far the most preferred control system in the world with over 1500 users.

WSF SmartClave® Autoclave Control Systems by WSF Industries, Inc.

Sterilization Process Controls Narrative Purpose/Importance The purpose of the production and process control subsystem (including sterilization process controls) is to manufacture products that.

Autoclave Control Systems

CPC (Composite Processing Control) is ASC's flagship software and control system designed specifically for control of composite processes in autoclaves, ovens, presses, formers, and bond tools. Since its creation, CPC has been at the forefront of composite technology. CPC Today

Autoclave Principle, Procedure, Types, Uses • Microbe Online

Autoclaves use steam heat to kill any microbial life that may be present on a contaminated load. A load — also known as goods — is considered sterile once it has undergone a full sterilization cycle.

Ve Programming Control Starter Kit Autoclave Control System

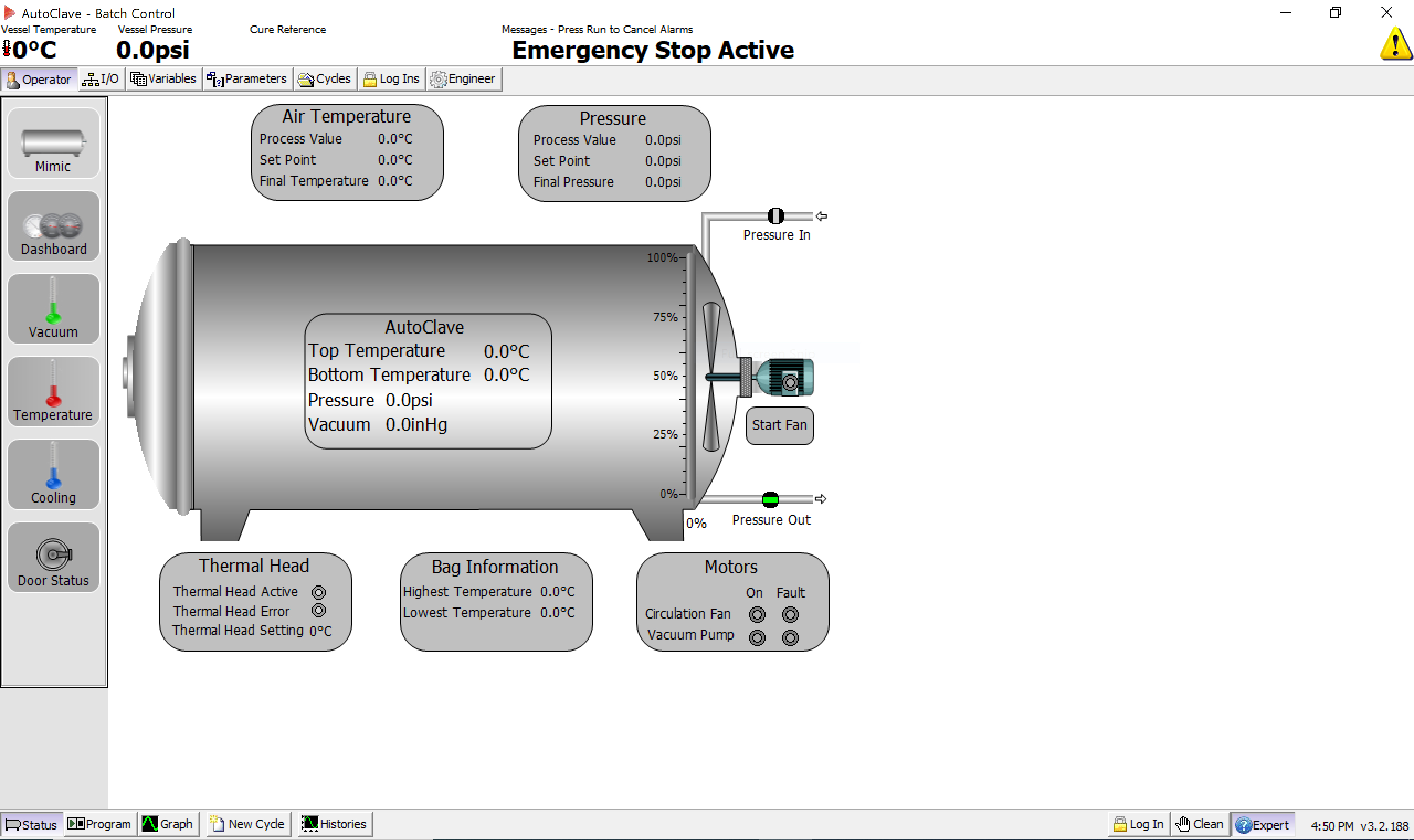

TEC's Autoclave Computer Control System (ACCS™) TEC's ACCS™ software package is designed to control the surroundings that influence the part or parts inside of the Autoclave. The current version of ACCS™ is TEC's third generation of software for Autoclave control.

How Does an Autoclave Work How to Use Autoclaves?

Our autoclave systems not only control and monitor the vacuum level to each part, but the CPC control system performs automatic leak tests prior to and during the run. Each leak test generates a report that becomes part of the permanent data record.

Composite Curing Autoclave Autoclave Control System XIRTUE

A CompuDAS autoclave Control System can be programmed to your exact recipe for the four major sterilization parameters: there are four parameters of steam sterilization: steam, pressure, temperature, and time.

Autoclave Control System Composite Curing Autoclave

CompuDAS Autoclave Control Systems manage and automate all aspects of the Autoclave curing process. The autoclave Control System can be operated from familiar user-friendly Windows based interface installed on any compatible PC. Each segment can be programmed for ramp times, temperatures, pressure or vacuum levels, and other parameters.

Autoclave Control Systems Upgrade Clark Nexsen Industrial

BTT PLC Control System. Bondtech Corporation's high performance control and data acquisition systems have been thoroughly proven in high-tech aerospace manufacturing plants. The BTT PLC control system is designed to provide maximum flexibility to address any site specific waste treatment requirements. BTT systems can be configured with the.

Koch LabProtocols/How to Autoclave OpenWetWare

Hodge International's world renowned autoclave Quick-Opening Door system is included on most Bondtech composite autoclaves in addition to standard features, such as:. Our control system complies with all current and known future requirements of governmental agencies such as the FAA, EASA, and all OEM aerospace composite parts requirements.